Build Smart Laser

News

Empower made its debut at the 2025 China International Industry Fair

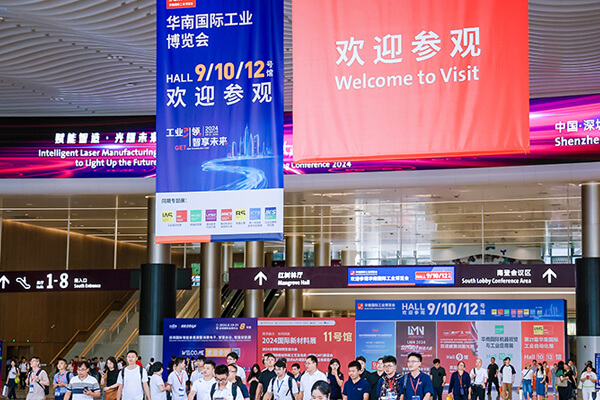

From September 23rd to 27th, 2025, the highly anticipated 2025 China International Industry Fair was grandly held at the National Exhibition and Convention Center in Shanghai. Empower made a spectacular appearance with its core product lineup, including three major A+B intelligent subsystems for laser cutting, laser welding, the GF multi-axis series, and robotic welding solutions. The exhibition comprehensively showcased Empower's profound technological expertise and forward-thinking strategies in the high-end equipment manufacturing sector, offering professional visitors an immersive experience where cutting-edge technology seamlessly integrates with intelligent applications.

Laser Cutting A+B Intelligent Subsystem

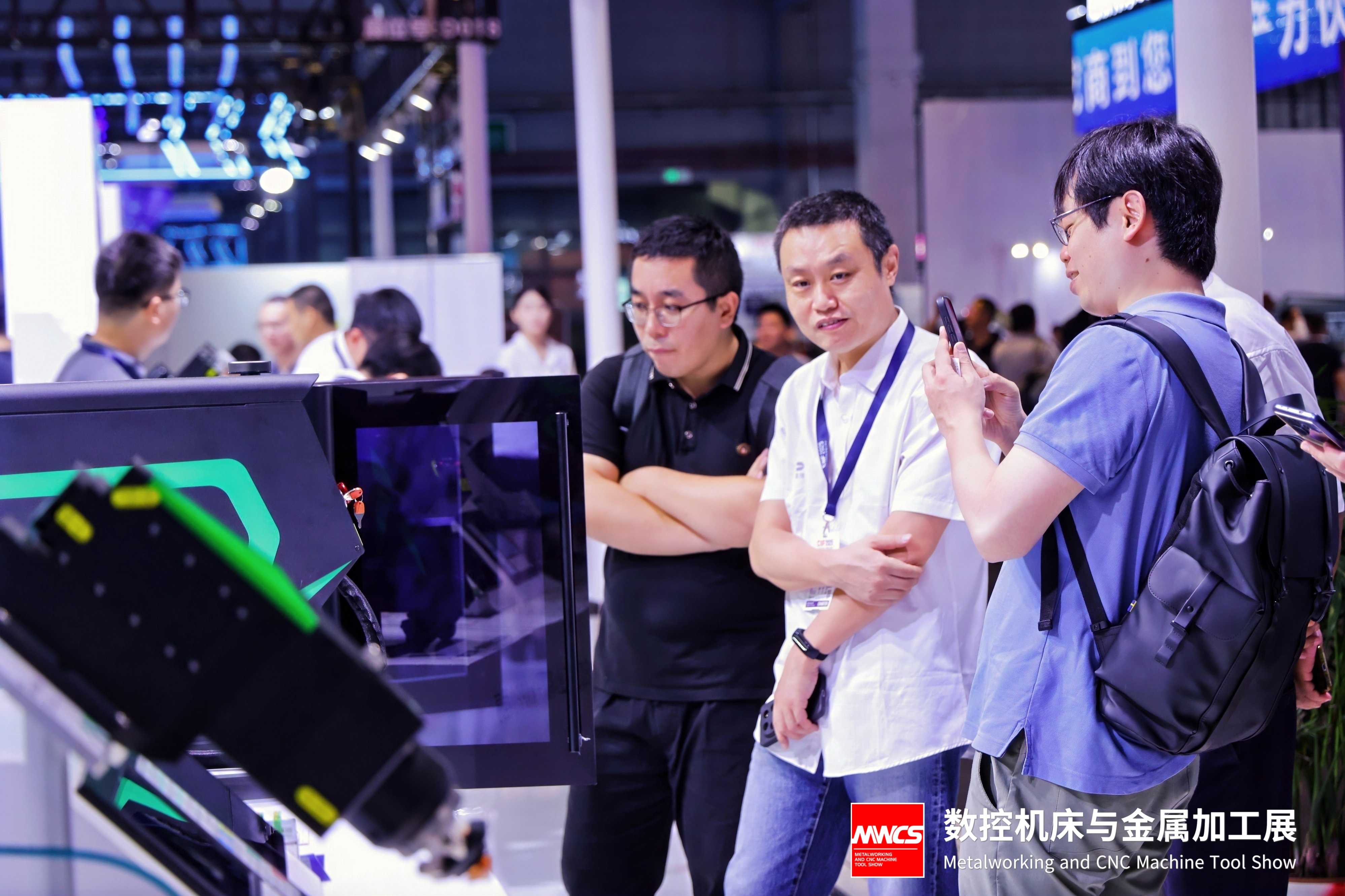

The laser cutting A+B subsystem, a key highlight of Empower’s showcase, drew significant attention at the exhibition due to its exceptional collaborative performance. This solution goes beyond simple hardware integration—through deep-level system synergy and intelligent optimization, it achieves a “1+1>2” effect. In particular, the ultra-high power focal shift compensation solution and the automatic centering adjustment solution displayed at the exhibition attracted considerable interest from visitors.

Ultra-High Power Focal Shift Compensation Solution

To address industry-wide challenges in ultra-high power laser cutting—such as focal shift and unstable cutting quality caused by thermal lens effects—Empower has independently developed a fully closed-loop focal shift compensation solution. By combining real-time temperature field monitoring with adaptive compensation algorithms, the system achieves precise control over the focal position. This solution significantly enhances the consistency and process stability of cutting operations. It not only improves cut quality markedly but also ensures reliable equipment performance under prolonged high-load conditions. This provides critical support for the scalable, high-quality application of ultra-high power laser cutting. Additionally, when paired with the SkyEye Residual Material Scanning System, it enables fully automatic scanning of leftover materials, automatically generates dimensional layouts of remnants, and performs optimized nesting on residual sheets once processing parts are imported.

Auto Beam Alignment Solution

The auto beam alignment solution, powered by the XC6000 system and the BS-CAT series intelligent cutting head, directly addresses core pain points of traditional manual calibration—such as low precision, inefficiency, and high upgrade costs. Utilizing high-precision vision and intelligent algorithms, this solution achieves automatic centering at an accuracy level of 0.01mm and enables automatic zero-focus calculation. It reduces what was once a minutes-long manual process to under 10 seconds, significantly enhancing both quality and efficiency. Featuring a unique modular design, the system allows existing CAT cutting heads to be rapidly upgraded by simply replacing the front cover plate. This eliminates the substantial losses associated with scrapping equipment or prolonged downtime, while drastically reducing upgrade costs.

Laser Welding A+B Intelligent Subsystem

In response to the growing demand for high-quality welding, Empower introduces the Laser Welding A+B subsystem as a comprehensive solution. The KW100 welding system, deeply integrated with intelligent control and adaptive process algorithms, is widely applied in gantry welding, robotic welding, and other fields. To align with industry usage habits and the need for low-application-threshold operation, the subsystem features an interactive teach-in interface, enabling welding program editing without coding. It also offers configurable interface development tools and a universal PLC program editor, supported by demos, development guidance, and customized development services.

The exhibition showcased the full range of welding products, including the BH handheld welding series, BW fixed optical path welding series, BF oscillating welding series, BG galvanometer welding series, hybrid welding series, and the cladding, quenching, and sealing edge series. The Laser Welding A+B Intelligent Subsystem demonstrates broad application potential in areas such as new energy vehicle battery welding, motor assembly, white body welding, as well as in precision electronics and medical device manufacturing. This highlights Empower’s technological leadership in delivering automated, intelligent, and high-quality welding solutions.

GF Multi-Axis Series A+B Intelligent Subsystem

Designed for high-flexibility motion solutions such as five-axis and complex surface machining, Empower's GF Multi-Axis Series A+B subsystem demonstrates robust capability in addressing complex three-dimensional laser processing challenges.

At the GF Multi-Axis Series Exhibition Zone, the XC5000 bevel cutting system stood out with its visual calibration, plate height compensation, and single-pass cutting capabilities. During bevel processing, the system collects data in real time and compensates for material deformation through its algorithm, enhancing machining accuracy. When cutting polygons and other shapes in bevel operations, the system automatically calculates the processing path and completes cutting in a single pass, significantly improving efficiency. The GF502 Gantry AB-Axis Bevel Sub-mechanism offers exceptional flexibility and scalability. It can be paired with cutting heads, welding heads, hardening heads, and other components of various specifications to achieve bevel cutting, curved surface welding, surface hardening, and more.

The XC4000T-A Tube Cutting Bevel System with Zero-Beveling-Length is equipped with the GF403 zero- beveling -length tube cutting bevel A+B subsystem. This solution is designed to address the efficiency bottlenecks and precision challenges inherent in traditional tube bevel cutting. By deeply integrating sophisticated mechanical design with intelligent control algorithms, the system ensures that the distance between the cutting head tip and the tube surface remains constant during bevel angle deflection. This results in more precise bevel angle control, consistent cut quality, and delivers a new experience of high-speed, high-precision bevel cutting.

Robotic Welding Solution

The robotic laser wire-feed welding solution consists of a push-pull wire feeder, an integrated wire-feeding laser welding head, a control cabinet, and a robot, with an optional molten pool camera. The precision of wire push-pull, retraction, and compensation can reach ±0.2 mm. The integrated coaxial wire-feeding nozzle effectively prevents interference issues compared to traditional off-axis wire feeding, offering more convenient operation. The laser head features collimation and focus adjustment functions, allowing flexible control of the focal position along the Z-axis. The system supports multiple communication methods, including I/O, Modbus TCP, and Profinet.

All-in-One Laser Hybrid Control System

At this exhibition, Empower proudly launched the EDK2025-6A All-in-One Laser Hybrid Control System. This system is a highly integrated, powerful laser processing control platform that consolidates multiple processes—including laser cutting, welding, cleaning, and engraving—into a single unit, providing comprehensive coverage for diverse laser processing needs. In terms of intelligence and usability, the system supports online pattern importing, in-process graphic editing, real-time parameter adjustment, and access to an online graphics library, significantly enhancing operational convenience and production efficiency. This allows users to quickly call up and modify processing programs. For motion control, it supports multiple drive methods such as EtherCAT, pulse control, hybrid servo, and stepper motors, ensuring reliable performance for high‑quality processing.

Precision Cutting Solution

The ultra-precision laser cutting dedicated system, equipped with Empower's laser cutting head, offers user-friendly operation, high equipment flexibility, and strong scalability, enabling efficient, high-quality precision laser cutting. Utilizing precision linear guides, the system delivers high positioning accuracy, minimal wear, and stable performance. It is suitable for ultra-precision cutting applications involving various metals such as carbon steel, stainless steel, aluminum, and copper, as well as non-metallic materials like ceramics and glass.

xChat SmartConnect

Empower officially launched its self-developed SmartConnect APP, born from the experience of shipping 200,000 laser heads globally and designed for smart manufacturing scenarios across thousands of industries. "SmartConnect APP" is harnessing the power of digitalization to make laser processing smarter, more efficient, and more worry‑free—embodying Empower's mission to "give laser intelligence and give manufacturing a soul." As an intelligent connectivity platform specifically designed for industrial settings, it is compatible with underlying operating systems such as HarmonyOS, Android, and iOS. It also enables customers to independently develop, deploy, and manage proprietary xAPP mini‑programs with intellectual property protection, earning it the title "WeChat for Smart Manufacturing." Through human‑machine interaction and device connectivity, SmartConnect APP achieves intelligent scheduling and efficient coordination of the five core production elements: personnel, equipment, materials, methods, and environment. It covers a wide range of scenarios including real‑time monitoring, process optimization, and data insight, providing a simple yet comprehensive one‑stop solution for industrial digital‑intelligent transformation.

Meanwhile, from September 23rd to 26th, Empower held consecutive daily launch presentations for its new products. Product line managers introduced the latest releases and R&D achievements showcased at the exhibition one by one.

The five-day exhibition concluded successfully, with Empower's booth attracting numerous visitors and partners who stopped by to observe, inquire, and discuss collaborations. During the live demonstrations, the stable, precise, and efficient performance of each system earned high recognition from the audience. Moving forward, Empower will continue to deepen its commitment to technological innovation, partnering with industry peers to drive the advancement of Chinese manufacturing toward higher quality and efficiency. Together, we will lead the laser industry from the era of tools into a new age of intelligent, open, and symbiotic ecosystems.